E-mail:sales@chinaolivet.cn

The welding industry has continued to grow over the years. With the increasing demand for welding services, more and more workshops are turning to automation. Are you one of them? Then there are some best practices for welding automation.

1. Start simply and cautiously

If you have just introduced automation in a welding shop, or are still in the planning stage, take one step at a time and be careful. Welding automation is a form of investment for enterprises. As with any new investment, water needs to be tested before it can be fully tested. Understand the requirements of the welding shop - use partial automation of welding manipulator or use full automation of robot.

Let your workers learn and adapt to the new additions. Identify room for improvement and potential risks, and find the correct solution. The introduction of new equipment and processes in the welding shop shall be carried out step by step.

2. Identify key cost drivers

Identifying key cost drivers in the operation is important to improve the overall production process. Conduct a detailed cost analysis of fixed and variable costs, taking into account the following factors:

What is the cost of producing a particular part/output

The total amount of time spent on a project

Equipment maintenance cost

The cost of productivity lost when a device fails.

The information you can glean from this analysis will allow you to develop a more cohesive strategy to focus on the more important factors in the store and reduce non-value-added activities. Once you understand the major cost drivers for the welding shop, you can adjust your processes accordingly to make the most of your resources and increase your productivity.

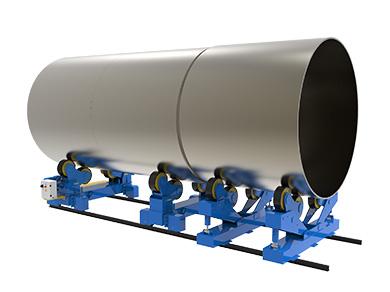

Wind Tower Production Line

3. Ensure good ergonomics

Like other industries in manufacturing, the welding industry faces the typical dangers of such workspaces. Ergonomics is a factor that should always be considered when managing a welding shop.

Here are some ways to control your store's working environment:

Establish a regular maintenance plan and follow it strictly

Ensure that your automated welding equipment remains accurate and repeatable

Make sure all welders are properly trained before joining the operation

Check out this blog post about welding dangers for more tips!

4. Select appropriate welding equipment and process

Different projects or situations may require certain welding processes and specific materials or equipment. For example, pipeline welding and other large-scale tasks require processes and equipment capable of high-strength welding.

It is also necessary to have perfect automation equipment. Choose equipment that provides the highest possible efficiency. If welding manipulators are used, a lighter, more powerful, more flexible device would be a perfect choice.

Sometimes, there is no welding manipulator or automation unit that can meet very complex project requirements. Automated good things can also be customized! Look for the right welding manipulator manufacturer to provide the perfect custom welding automation solution for your welding workshop.

5. Adapt to any changes

Manufacturing is on the rise. There are new trends and new approaches. As an enterprise trying to stay competitive in the market, operators must keep abreast of these innovations and always adjust accordingly.

To remain competitive and continue to improve, companies should recognize the need to invest in personnel training and the acquisition and maintenance of materials and equipment. This may require operators to try something new, and the rate of return on unit cost can determine whether it is worth a try.

You can spend a lot of time, effort, and resources simplifying better processes to maximize the productivity and efficiency of the welding shop, but don't forget the next step - back up your strategy with action and continuous improvement plans.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod