E-mail:sales@chinaolivet.cn

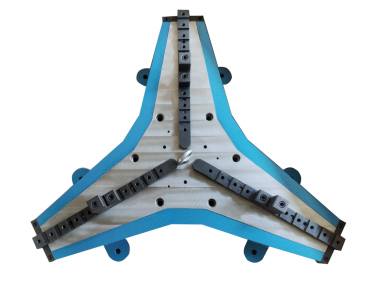

Welding positioner Welding chuck is an important part of automatic welding positioner. It requires frequent maintenance and maintenance. When special circumstances occur, the maintenance frequency of welding must be increased. This can greatly prolong the service life of the welding chuck, improve work productivity, and the auto welding positioner manufacturer will share with you: the correct maintenance method of the welding chuck.

1. After the chuck is used, the welding chuck body and the surface of the slideway must be cleaned with tools such as air guns. This can ensure that the welding chuck has good accuracy after long-term use, so the welding chuck is regularly lubricated. Work is important.

2. Apply molybdenum disulfide grease (color is black) at least once a day. Put grease into the welding chuck grease nipple until the grease overflows the jaw surface or the inner hole of the welding chuck (the inner hole protective sleeve and the connecting nut).

3. In order to prevent rust inside the welding chuck, the holding force is reduced and the workpiece cannot be clamped. Therefore, it is best to use cutting oil with anti-rust effect. Use of cutting oil can prevent rust inside the welding chuck.

4. The welding chuck body and slide surface must be cleaned with an air gun or similar tool when the operation is completed.

5. Remove and clean the welding chuck at least every 6 months, keep the sliding surface of the jaws clean and lubricate, and increase the life of the welding chuck.

6. Inspect all parts for cracks and wear. Cut the cast iron thoroughly at least once every 2 months. If the parts are seriously damaged, they should be replaced with new ones immediately.

7. Different clamping methods must be used for different workpieces. If it is used to clamp irregular workpieces, the welding chuck will be damaged.

8. When the welding chuck pressure is abnormal, clamp the workpiece under high pressure, which will reduce the service life of the welding chuck, so when it is found that the welding chuck gap is too large, it must be replaced with a new one.

Welding Chuck

The development of welding positioners in the machine tool industry has developed along with the development of the welding structure of machine tool products. welding chuck exporter believes that the leading products of China's machine tool industry are mainly metal cutting machine tools, forging machinery products, casting machinery products, woodworking machine products, tool products, abrasive tools and machine tool accessories products. Among them, metal cutting machine tools, forging machinery and casting welding positioners are the main fields of application of positioners in the machine tool industry.

The welding positioner has also gradually developed into the leading process of the machine tool industry, which is mainly reflected in the following aspects:

(1) Some key enterprises have established a welding workshop or metal structure factory with a certain scale and established a complete welding management system. Absorbed the welding process standards of imported products, implemented national professional standards, and formulated enterprise standards.

(2) The welding process has been improved, from a single processing technology to a set of emerging comprehensive engineering technologies from raw material pre-treatment, cutting blanking, forming, welding, post-weld detection and post-weld processing.

(3) Numerical control precision cutting and computer-programmed nesting technology have been applied, and changed the traditional manual cutting blanking, reducing mechanical processing.

(4) The new technology of vibration aging is promoted to achieve the purpose of reducing and homogenizing the residual stress of the welding structure, reducing the deformation of the weldment and stabilizing the accuracy.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod