E-mail:sales@chinaolivet.cn

By better understanding the causes of corrosion of welded joints and the corresponding prevention methods, we can effectively reduce the probability of this type of corrosion and the economic losses that it brings.

By definition, corrosion usually refers to the degradation of material properties caused by chemical or electrochemical reactions between the material and its surrounding environment. Although this is generally a problem with metal materials, special attention should be paid when handling welded joints. Because even if you select the appropriate metal and filler metal, comply with all operating standards and perform the welding correctly, corrosion will still occur.

Corrosion is generally caused by three basic factors: material, environment, stress and load. These factors can cause damage independently or together. Due to changes in chemical composition, different materials may contain different residual stresses and form different discontinuities at the welded joints. All these factors will become a problem when looking at the properties of welded joints.

Since corrosion has been a very complex research topic since ancient times, although many researchers have tried to classify these unwelcome corrosion and mechanisms, most of them have not achieved good results. So far, according to the mainstream school of thought, the corrosion mechanism can be classified according to factors such as its source and scope, material separation mechanism and its physical appearance.

Welding equipment supplier shares this article for you.

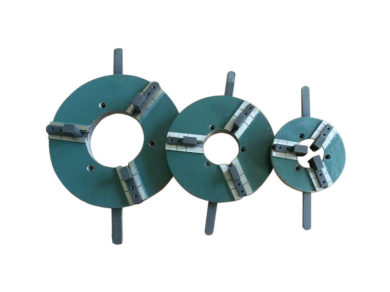

Overview of Corrosion Causes and Mechanisms of Welding Chuck

The corrosion of welded joints is mainly caused by manufacturing and metallurgical factors. These defects include but are not limited to: weld design defects, poor welding practices, various welding defects (details and unacceptable defects missed in non-destructive testing), welding cracks and residual stress, and various metallurgical reasons.

The welded joint structure has three different areas, each with different mechanical and structural characteristics. The fusion zone is the part where the matrix and the filler metal are mixed, and the chemical and structural composition of each metal may be completely different. Between the fusion zone and the substrate is the heat-affected zone (HAZ), whose structural characteristics are different from those of the substrate. Due to the difference in composition and electric potential, this structure is one of the main reasons for welding corrosion, and due to the deformation caused by heating during the welding process, there will always be residual strain in the joint.

This means that even if some precautions have been taken to prevent these corrosions, the neglect of these structural and geometrical changes can still lead to various forms of corrosion in this particular area, and it is usually unexpected corrosion.

Typical corrosion mechanisms in welds include galvanic corrosion, stress corrosion cracking (SCC), fretting corrosion, cavitation, high temperature corrosion, various forms of local corrosion (such as pitting and crevice corrosion), fatigue corrosion and hydrogen cooling Cracked. Since all the corrosion mechanisms mentioned here are electrochemically related in nature, they require the presence of electrolyte (such as water), which makes the pipeline particularly fragile.

Galvanic corrosion

Galvanic corrosion is not limited to welded joints, but is a kind of corrosion caused by the chemical composition of the weld base metal and the metal in the fusion zone.

Although some metals can be welded automatically (that is, using the same filler material as the base material), in most cases, the composition of these materials is slightly different, usually to ensure that the mechanical properties of the welded joint are consistent with the rest of the welded parts.

In the latter case, the weld metal will generally have a different potential than the base metal. This potential difference, coupled with the presence of electrolyte, is a necessary prerequisite for galvanic corrosion. This is the same principle as some standard batteries: two metals form a galvanic couple, electrons are transported from the anode (in this case, the metal with a lower potential) to the cathode, and the positive ions move in the opposite direction. Although this mechanism generates voltage in the battery, the lower potential material is preferentially corroded in the welded joint.

For example, for most aluminum alloy materials, the weld metal and heat-affected zone become more difficult to corrode than the base metal, which means that the base metal is more prone to electrochemical corrosion. When austenitic filler metal is used to repair high-strength low-alloy (HSLA) steel, similar results may be produced.

Welding methods to reduce corrosion

Although it is almost impossible to completely prevent welding corrosion, there are several methods to minimize the probability and impact of its occurrence.

Some of the more important aspects include: the metal materials must be carefully selected to have the best possible chemical compatibility with the operating environment. Properly cleaned and treated surfaces have fewer physical defects, which may be the starting point for some forms of corrosion, so careful selection of surface cleaning and treatment methods is also very important.

Undercuts, cracks, and irregular shapes of the weld surface and the root of the weld may be the cause of several different types of corrosion, especially cavitation, pitting and crevice corrosion. To avoid these problems, several steps must be taken: the root of the weld must be penetrated and deposited correctly. If arc welding or automatic powder welding is used, the slag must be removed after each weld; the surface finish must be uniform and smooth, and it is best to oxidize the surface to prevent further corrosion.

The correct choice of post-weld heat treatment (PWHT) can release some or all of the residual stress and protect the welded joint from some forms of corrosion. It can also release some trapped hydrogen and partially homogenize the material to reduce the potential difference. In addition, passivation treatment can remove surface contaminants and form a new uniform passivation oxide film on the surface, so stainless steel can be protected from corrosion.

Wuxi OLIVET Machinery Equipment Co.,LTD.E-mail: sales@chinaolivet.cnTel: +86-510-8383 0908

Home About UsProductsQuality ControlCompany NewsContact Us Sitemap

Copyright©2015 Wuxi OLIVET Machinery Equipment Co.,Ltd. Technical Support: Reanod